When it comes to innovative solutions, NC’s Walker Advanced Manufacturing Innovation Centre (WAMIC) has the recipe for success – and the proof, it seems, will be in the ganache.

Thanks to a unique collaboration between WAMIC and the School of Culinary Arts, students from the new Baking and Pastry Arts Management program now have specialized ganache trays at their fingertips.

Indispensable tools for pastry chefs and chocolatiers, the chocolate ganache frames were highly sought-after for the program but they can cost a lot of ‘dough’ – the pricetag for a single specialized frame can be hundreds of dollars. Challenged with finding an affordable solution, Craig Youdale, Dean of Culinary, Tourism and Beverage Studies, applauded staff and students at WAMIC who had the expertise and cutting-edge equipment to help.

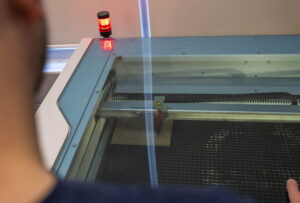

“It was a great collaboration between our WAMIC team in Welland and our pastry team in Culinary, Tourism and Beverage Studies [at the Daniel J. Patterson Campus in Niagara-on-the-Lake],” Youdale said. “Neil Wilkinson at WAMIC and his co-op students were able to use the Advanced Manufacturing Centre’s resources to make a custom part using the laser CNC cutters, and we saved a ton of money in the process. A win-win for all our students and divisions.”

The project came together in mid-August. Neil Wilkinson, Associate Director at WAMIC, said that the culinary team initially approached them with the idea of using 3D printers to create ganache trays. After researching the needs of the baking experts and specific requirements, they opted to use laser cutters to slice the frames from an acrylic sheet. Within a week, they had whipped up about 100 frames for the College’s Baking program.

For Ty Lozon, a Mechanical Engineering Technology student who worked on a co-op placement at WAMIC during Spring term, the project was a chance to put his skills to the test. With a passion for design and a knack for understanding how things work, he designed the frames using Auto CAD Inventor software. Once his drawings were approved, he baked in some new skills while learning to use the laser cutter.

“I feel that the experience gained through this project was useful to help me familiarize myself with equipment I had not much interaction with, in the past,” he said.

The icing on the cake: knowing that his work would serve other NC students.

“I’m very happy to know that students in another program will make use of something we made at WAMIC,” said Lozon. “Knowing that my work is being used and not sitting on a dusty shelf somewhere does grant some sense of accomplishment and pride.”

Through co-op placements and employment opportunities at innovation centres within the College’s Research and Innovation division, students like Lozon are equipped with valuable experience as they work on real-world projects. In December 2024, NC earned the ranking of No. 1 research college in Canada for the second year in a row.

While learning to use new equipment certainly helps to boost a student’s resume, one of the biggest benefits of working a co-op at WAMIC is learning how to interact with clients, noted Wilkinson.

“There is a lot of communication required at the beginning of a project to ensure we understand the client’s needs, requirements, parameters, etc., so we can do the job right the first time,” said Wilkinson. “Learning to own mistakes and communicate them to leaders and clients is a valuable skill.”

Though staff and students at WAMIC typically focus on providing solutions for small- and medium-sized businesses, they also occasionally take on community engagement initiatives. Their project to assist the School of Culinary Arts was one of them.

“We are very fortunate at WAMIC to have had great support from Fed Dev, NSERC, OCI, CFI, ORF and NC, et cetera, to outfit the centre with leading-edge equipment. We use it a lot in our applied research and technical service work with manufacturing companies in southern Ontario, but there is usually some additional machine time to do these community engagement projects.” said Wilkinson. “Let’s be good colleagues and help out our friends in culinary. It’s a win-win-win.”

In the end, NC’s School of Culinary Arts received their specialized baking equipment and only had to dish out $15 per frame to cover the cost of materials. The ganache frames are now ready to be used by students from the Baking and Pastry Arts Management program for their future creations.

- Staff and students at WAMIC opted to use a laser cutter to create to ganache frames for the School of Culinary Arts.

Baking and Pastry Arts Management is a two-year diploma that recently launched at the Daniel J. Patterson Campus in Niagara-on-the-Lake. After building a foundation in the fundamentals – sharing a common first year curriculum with the Baking and Pastry Arts certificate program – students dig into creative design, food science, and product innovation during their second year.

The Walker Advanced Manufacturing Innovation Centre offers a suite of services using leading-edge technology, including equipment and software, as well as expert staff to support industry innovation and commercialization of new products and processes.